camQuix Automatic Tool Assignment

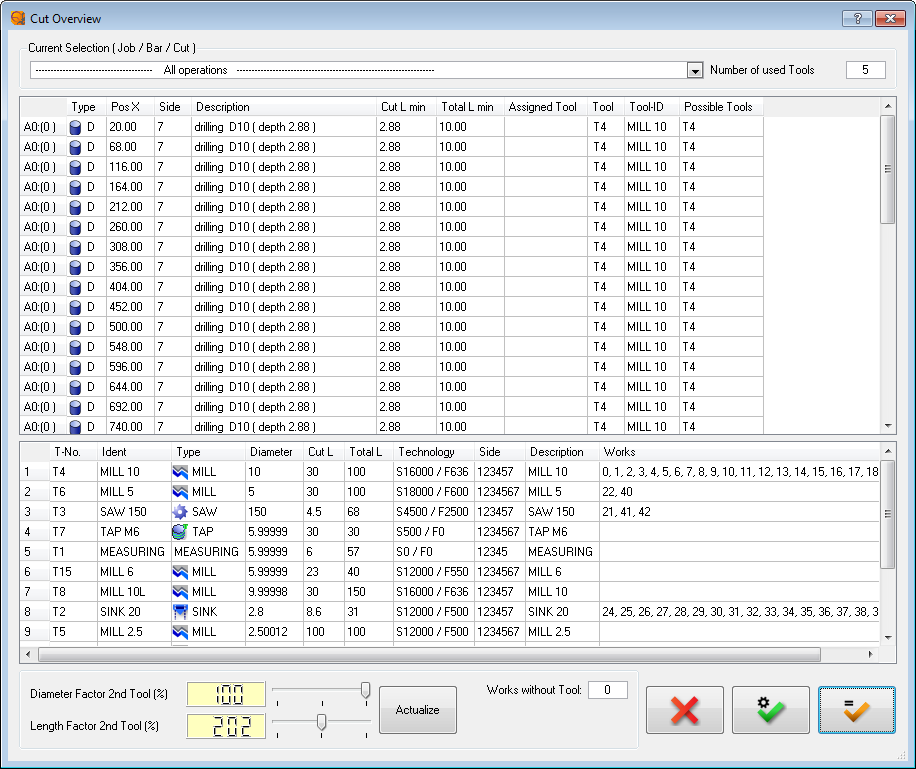

- Operations’ position and dimensions are analyzed in order to define a tool that is ABLE to do this work.

- Then, the tools of the machine (imported on the fly if it is connected) are assigned in an optimal way to reduce the number of tool changes.

- Now the sequence is optimized and the optimal positions of the clamps are calculated by using the 3D – collision control.

In this window you can manually change tools dimensions which in return will change the tool assignment. Once the system is set up correctly all of the above processes run completely automatically. A change to different toolsets or different target machines is very simple!