A lot of our customers like the simple and direct programming. Although this function is offered by several profile milling centres, often it is only possible by preparing a number of individual macros specific for this type of machine and (even worse) for the actual tool-set.

A direct graphical control with a 3D-view or a collision control is often missing (or is very poor).

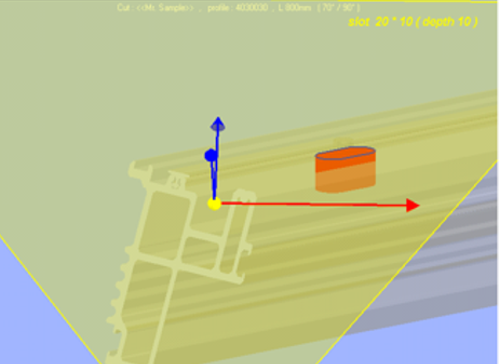

With camQuix you get software with a fast and easy to use programming interface. You will program completely independent of the machine type or the tools – this information will be automatically added by the system later . All input is defined by pure geometrical definitions (position and dimensions) and can be easily controlled in the 3D – window.

Generated programs are saved in a machine independent manner. Just before they are exported to the target machine they are complemented by the missing technological parameters (automatically!).

The internal powerful script language controls the output in NC-code and can be easily adapted to any new machine type.

Definition of Free Millings (Free Contours)

We have paid special attention to the process of entering free contours (which are often neglected in some systems). All movements are shown in a simple list and can be edited on the fly. You can change between absolute and relative system of co-ordinates.

Material Detection

A lot of processing time can be saved by utilizing of the depth tables for operations, which can be detected automatically.

4 / 5 – Axis Operations

The definition of operations on inclined planes is made easy in the following way:

1st you define a plane (based on a standard plane, like the TOP face), which can easily be rotated around one or two axis (A and C). On this new plane you can work easily like on a standard face. The complexity for new operations is reduced to a minimum …