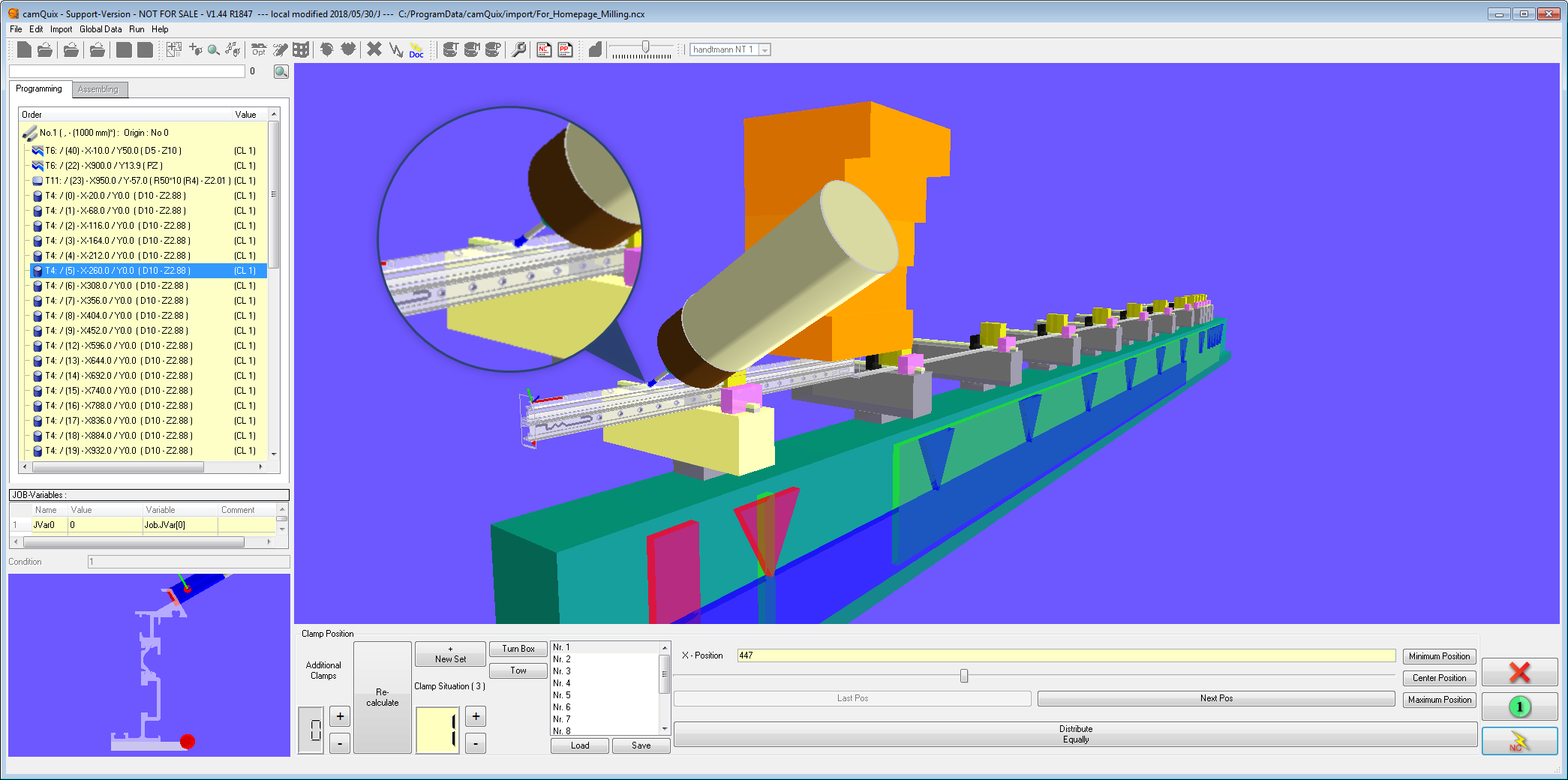

camQuix® is a modern CAM software for aluminum profile milling. Our experience from the last 20 years and constant development according to the latest standards of all the various machining centers have made camQuix a powerful and convenient tool. camQuix enables the automatic direct control of all your CNC machines as well as communication with peripherals.

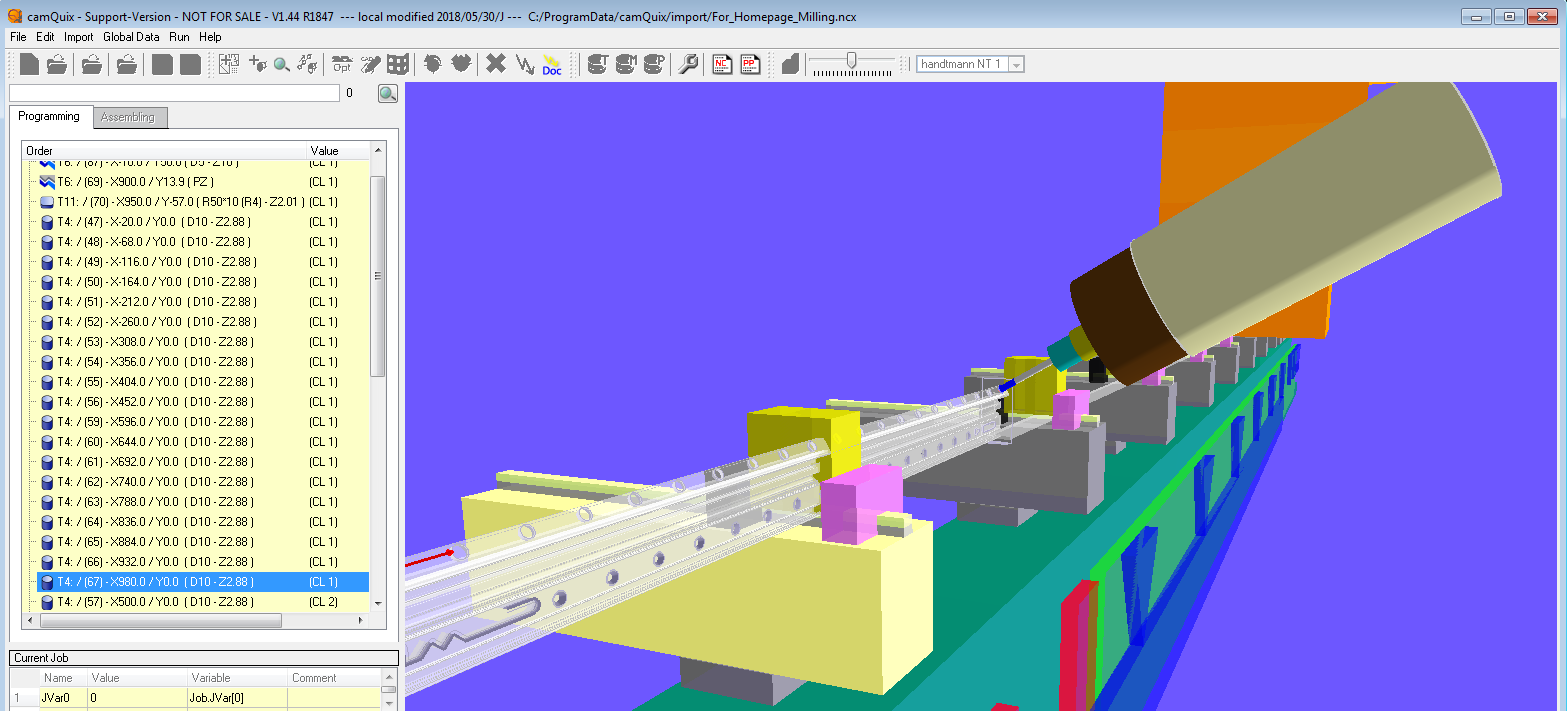

Within the clear structured user interface, you manage your entire CNC-machine park and your complete customer orders. Program different profile types and profile lengths target-machine-independent in a clear 3D graphic display.

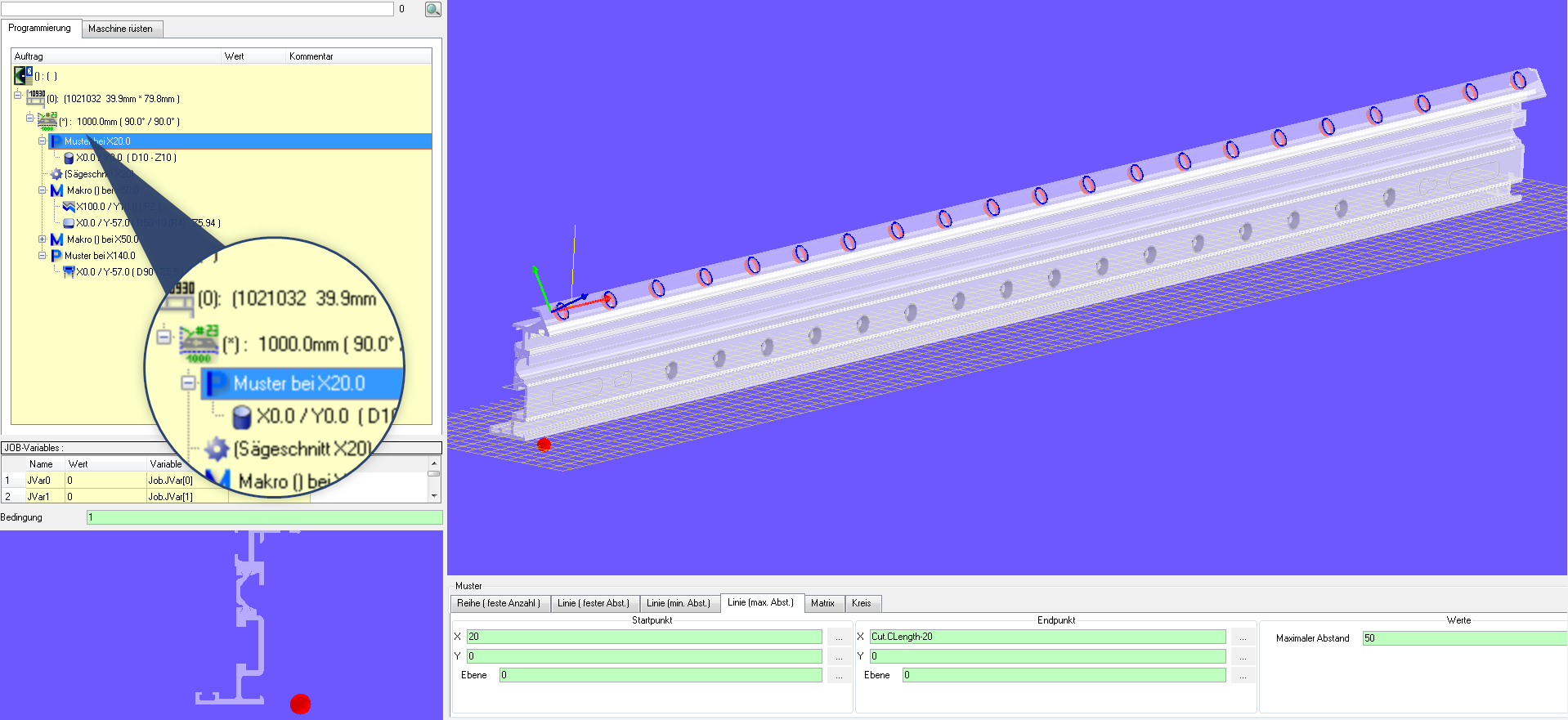

camQuix optimizes, among others, either machine- or project-related the loading positions of entire profile bars or profile cuts. Manage all your profiles within an intelligent data base and save repeating works as custom macros.

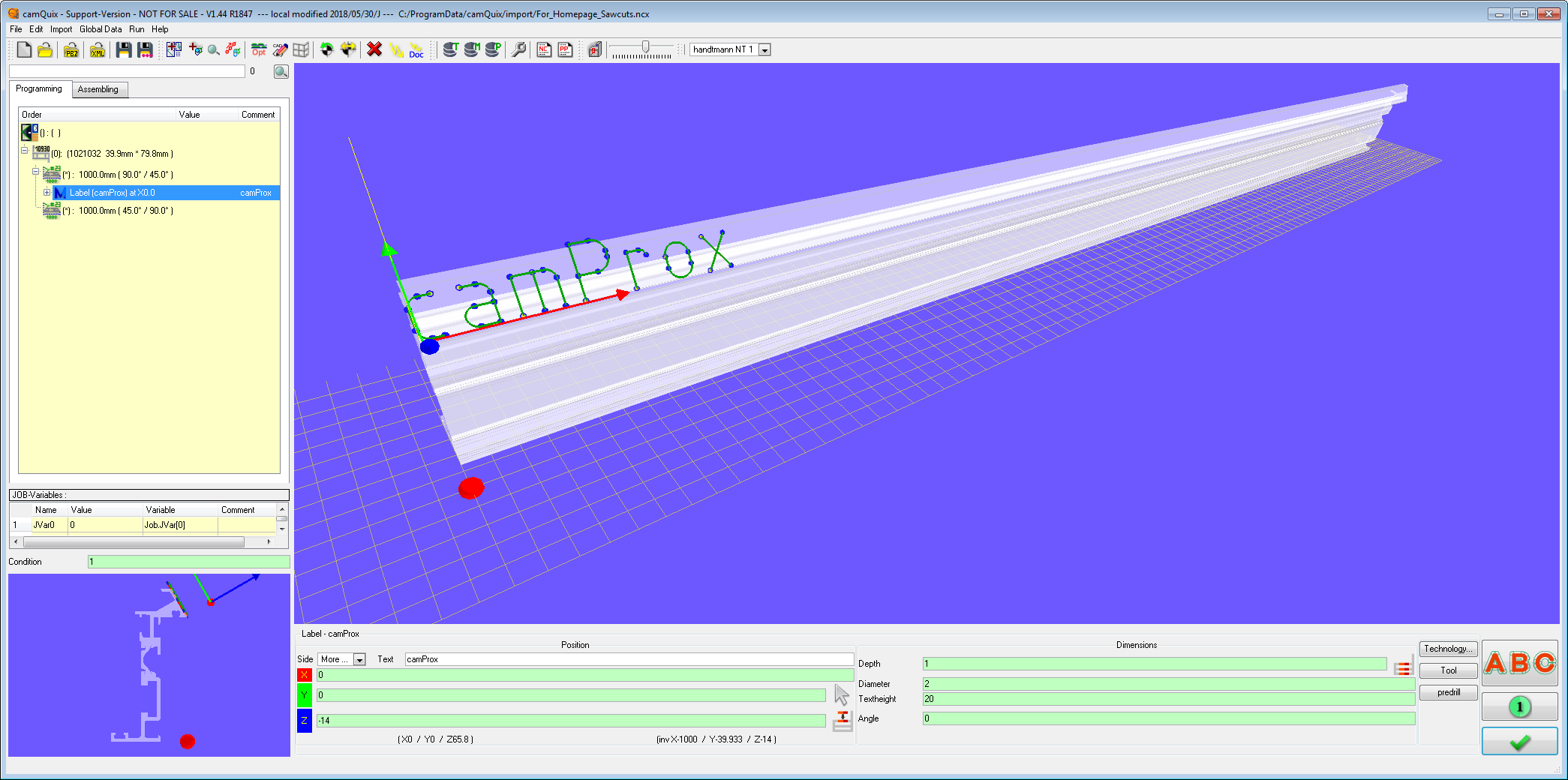

camProx provides furthermore cadXtract interface. cadXtract converts your 3D CAD-drawings into CAM-readable data automatically and it is of course fully compatible with camQuix.

More information about camQuix CAM-software you’ll find in the download brochure:

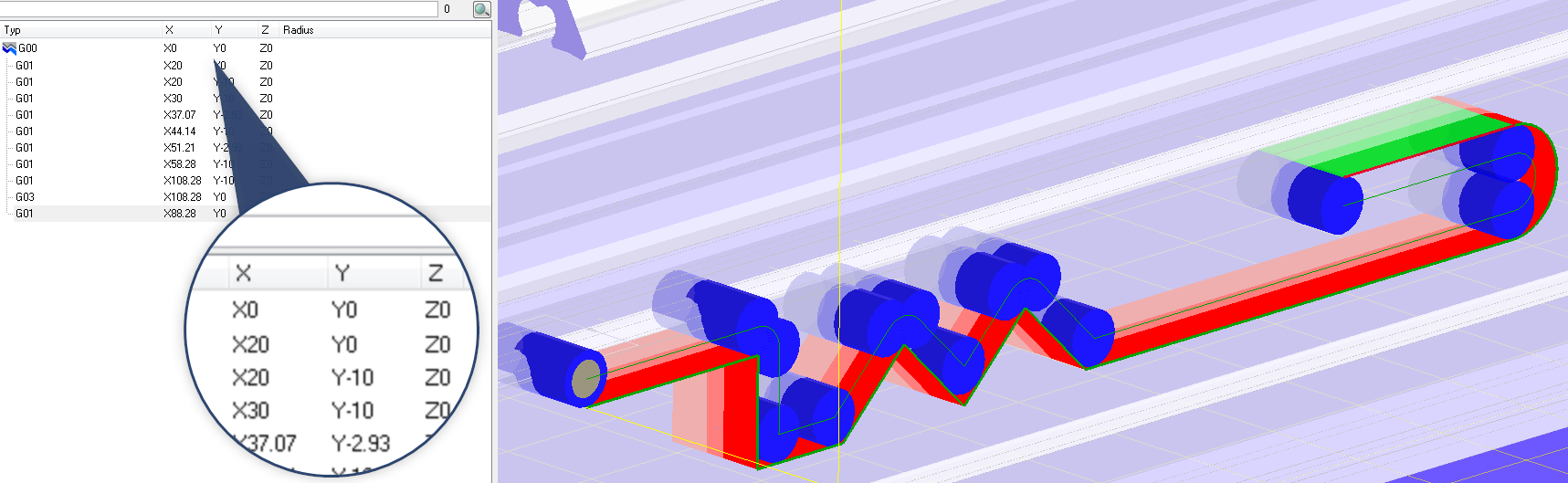

Fast programming of free contours

In camQuix, every work may be processed as a standard work, for example drilling, slot, rectangular pocket. However, free contours save production time and provide for high quality results. Especially for the production of free millings, camQuix is easy to use. Complex milling movements can be imported from DXF drawing lines. Tool radius compensation is automatic (G41/G42). What is really special about free milling is the ability to parameterize complex works. That means that every free contour can be defined via variables and saved as a macro. If the work has to be made again, it’s sufficient to change the values of the variables.

camQuix supports

- various origins

- tool length scanning / correction

- measuring head

- bar length scanning

- chip conveyor, test run, dry run

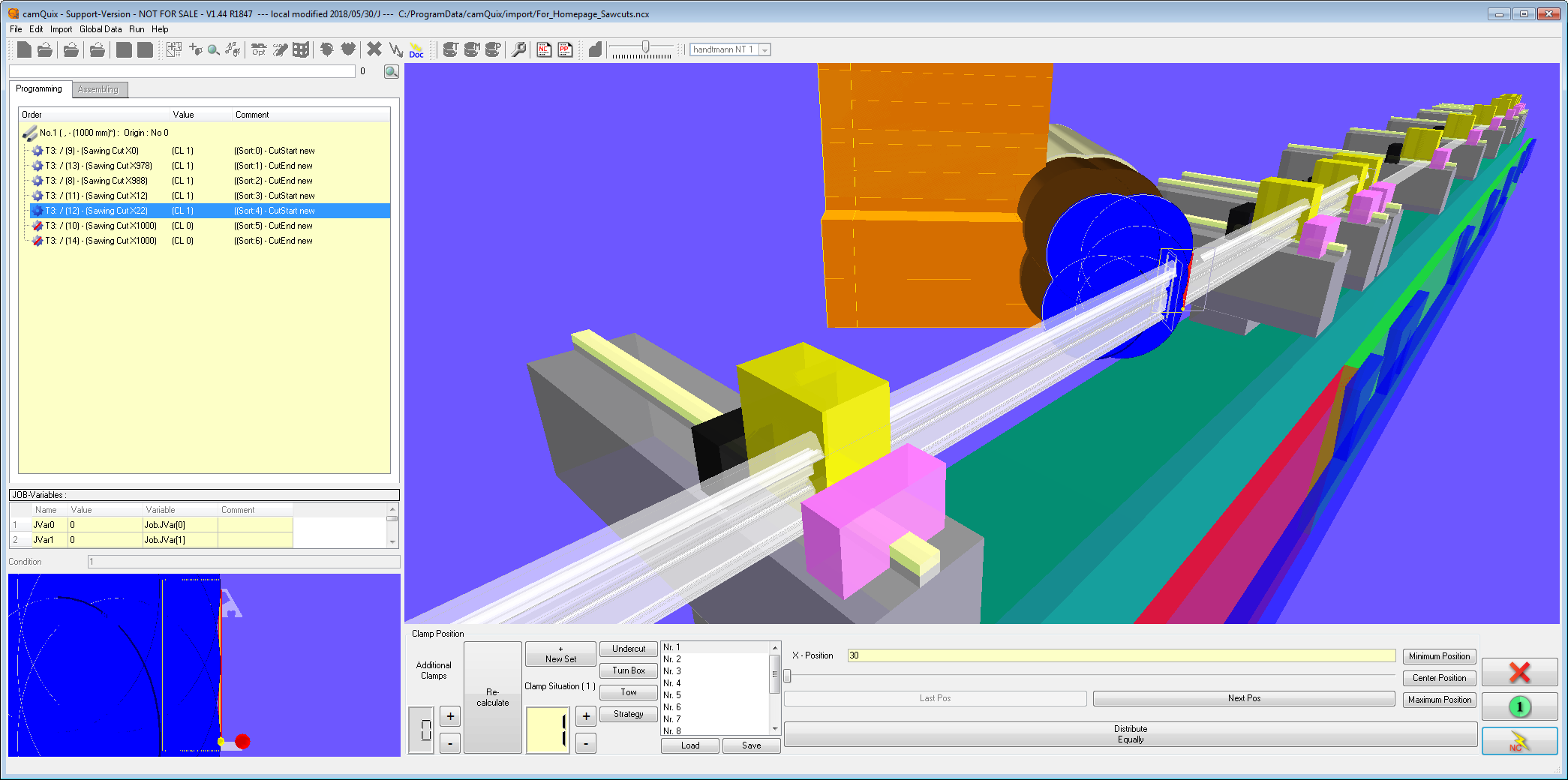

- machines with multiple clamping

- pushing centers

Functions overview for camQuix

- suitable for ALL machine types

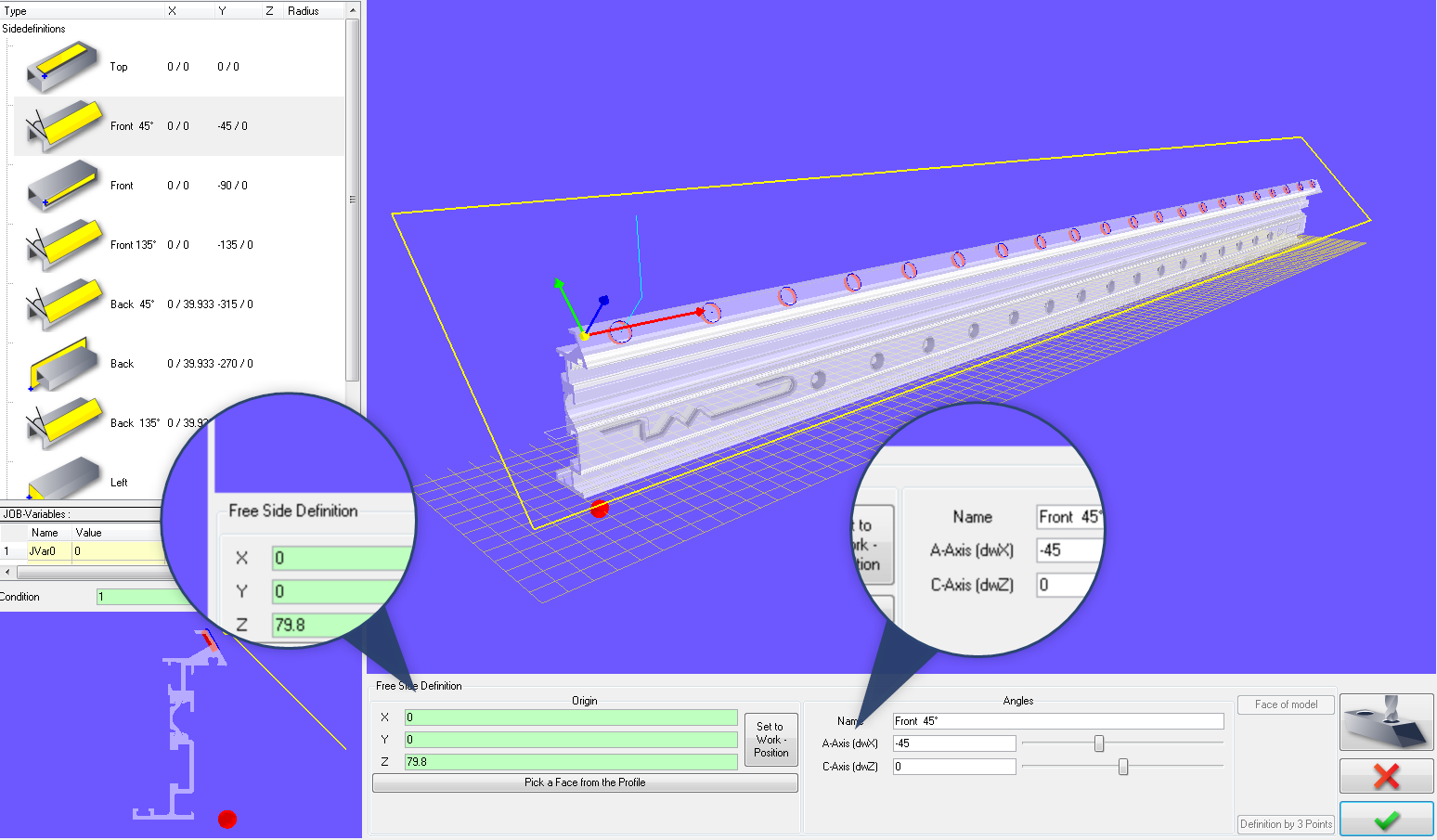

- 3/4/5 axis functionality

- central, machine-independent programming in one single user interface

- user interface for all works

- automatic depth table

- parameterizable construction: flexible free milling contours thanks to variable coordinates

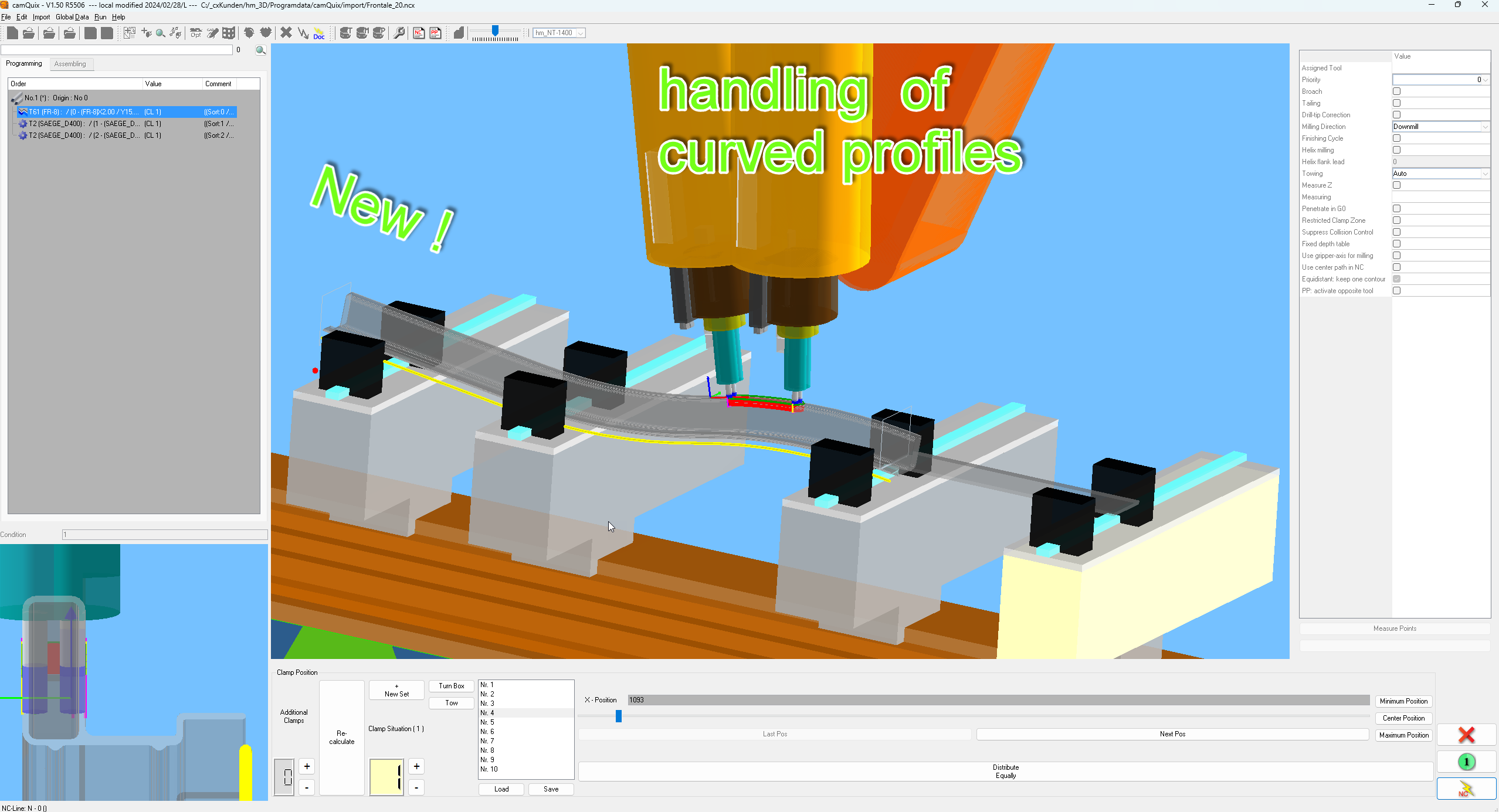

- intelligent clamps’ managing and reliable collission control

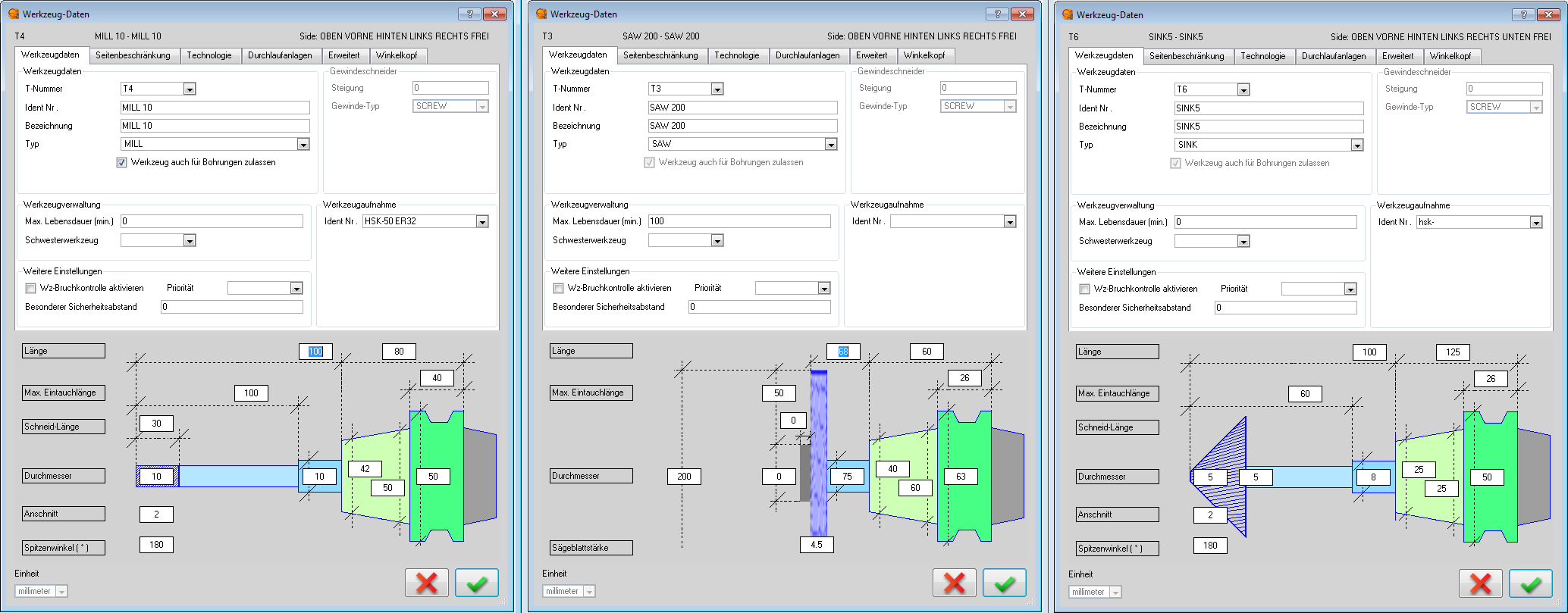

- automatic tool assignment

- cnc machining simulation with spindle and clamps-view on the machine bed

- data base for clamping cauls

- import of the DXF-format for free contours

- Pick-Function – select any point in your profile as reference working coordinates

- creating custom macros in a data-base

- flexible adaption to your production process

- direct control of pushing centers

Learn more about the full range of camQuix’ functions

- programming with camQuix, define free millings, change between absolute and relative coordinates and more

- data import from other software

- efficient production by camQuix’ automatic tool assignment